Established in 1996, SAC Serigrafia, has grown with a strong work ethic, keeping pace with screen

printing techniques.

In its long experience SAC Serigrafia has completed projects for various sectors, from industrial components to Luxury Packaging, from the Automotive to the fashion industry and the advertising sector, collaborating with important Italian and international businesses.

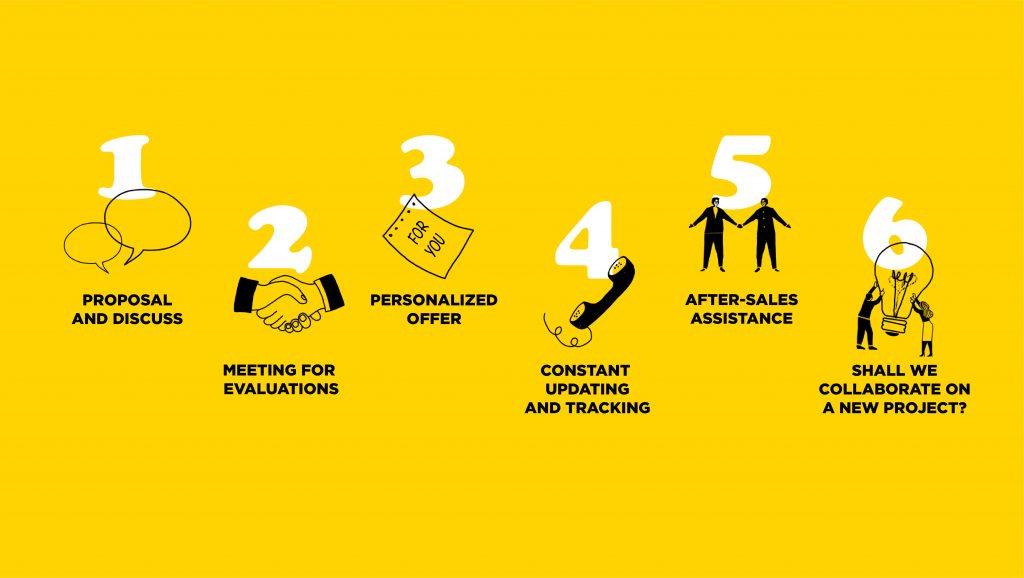

Over the years, technologies have evolved, together with modern processes and client care. Our approach has not changed, as the desire to develop new and unique solutions with the client.

We like to offer solutions in real time, thinking from the clients’ point of view, anticipating their needs.

Thanks to customer experience feedback, we have adapted our work method to cater for the individual client, to follow their needs with attention, saving them time and energy.

In other words, our aim is to offer the client the best of SAC Serigrafia in every moment.

After the Lean revolution, SAC Serigrafia has entered into the era of 4.0 industry.

Vertical warehouses, MES software, big data… which mean more reliability, precision and efficiency for the client.

Alongside our technical development, in line with the vision of continued improvement, there is the professional growth of our personnel through constant training.

SAC Serigrafia’s commitment to the environment is developing in two areas:

FOR OUR CLIENTS

INTERNALLY

© 2019 - SAC Serigrafia s.r.l. - Sede Legale: via E. Minato snc - 31030 Vallà di Riese Pio X (TV) ITALY - C.F. e P.I. 04090340268 - R.E.A. TV n. 322097